Rheology Automation

Matthew J. Hudson [1], David Meehan [2] & Sven L. M. Schroeder [1,2]

[1] School of Chemical Engineering and Analytical Science, The University of Manchester, The Mill, Manchester, M13 9PL, UK

[2] School of Chemistry, The University of Manchester, Brunswick Street, Manchester, M13 9PL, UK

Objective

To produce a versatile automation system that can be applied to standard laboratory equipment quickly and inexpensively to increase productivity of formulation and analysis of new mutli-component blends.

Design

A fully automated sample handling system must meet the following design specifications; it must be able to accurately formulate and blend samples from a number of feedstocks, it must be able to load and unload the sample into the instrument, the system must be self cleaning and have user-friendly and versatile software for experimental input and data output. Our main aim is to produce something that is functional as well as cost effective.

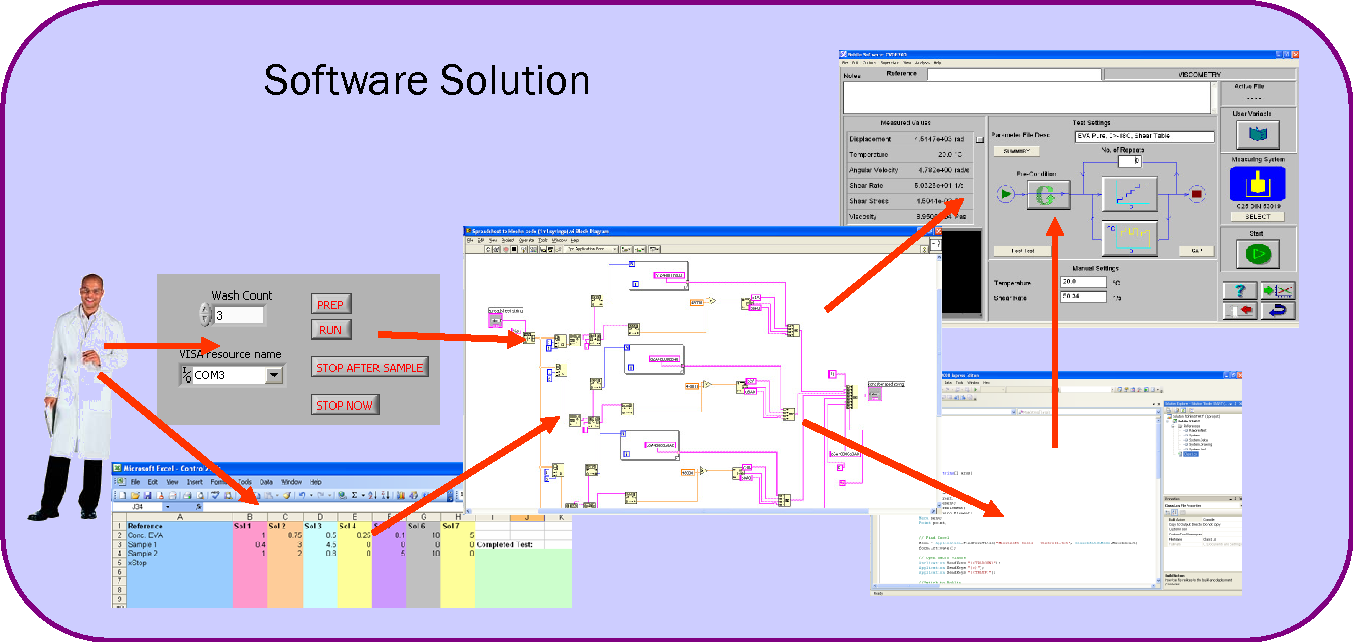

Software

Versatile Control Software has been written in LabVIEW™. This uses a simple user interface to enter experimental parameters and can be adapted quickly for use with various instruments. The user inputs all experimental parameters into a spreadsheet interface and then uses a simple ‘run’ button to start the system – the rest is carried out automatically.

Applications

The example system displayed here is attached to a Bohlin C-VOR bench-top rheometer. We have also used this system to automate a UV/Vis spectrometer, a mass spectrometers and for XRD measurements of lfuid systems. We have also successfully used automated data analysis and linked the results with a genetic algorithm computer which can intelligently decide on the next set of experiments to run in order to solve a pre-defined problem. This information can be fed back into the automation system in a perpetual loop until the solution is reached.

Summary

- Automated formulation and fluid handling system designed, built and tested.

- Screening of hundreds of formulations a week is now possible with minimal user input & cost.

- Easily adaptable for many instruments and genetic algorithm analysis to drive experimentation.

(c) 2010 Matthew J. Hudson, David Meehan & Sven L. M. Schroeder

Project supported by: